TTPA

| CAS number: | 177799-16-5 |

NPNPB

| CAS number: | 936355-01-0 |

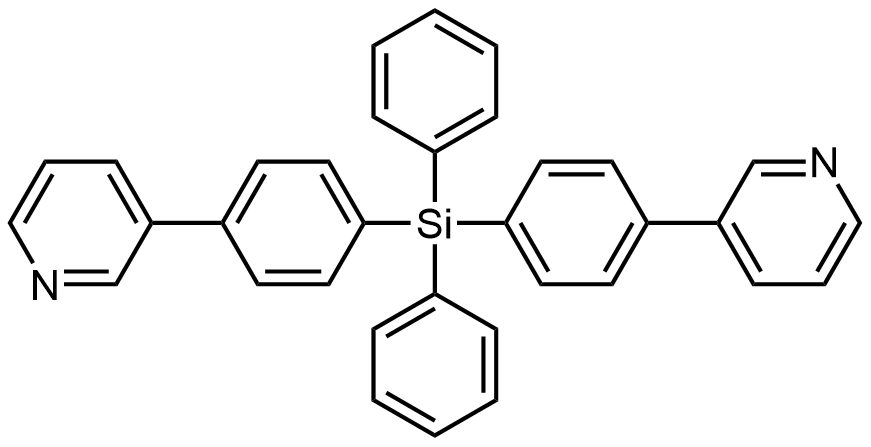

TSPO1

| CAS number: | 1286708-86-8 |

Tris-PCz

| CAS number: | 1141757-83-6 |

B2PymPm

| CAS number: | 1266181-51-4 |

B4PyPPm

| CAS number: | 1097652-83-9 |

B3PyPB

| CAS number: | 1030380-38-1 |

B3PymPm

| CAS number: | 925425-96-3 |

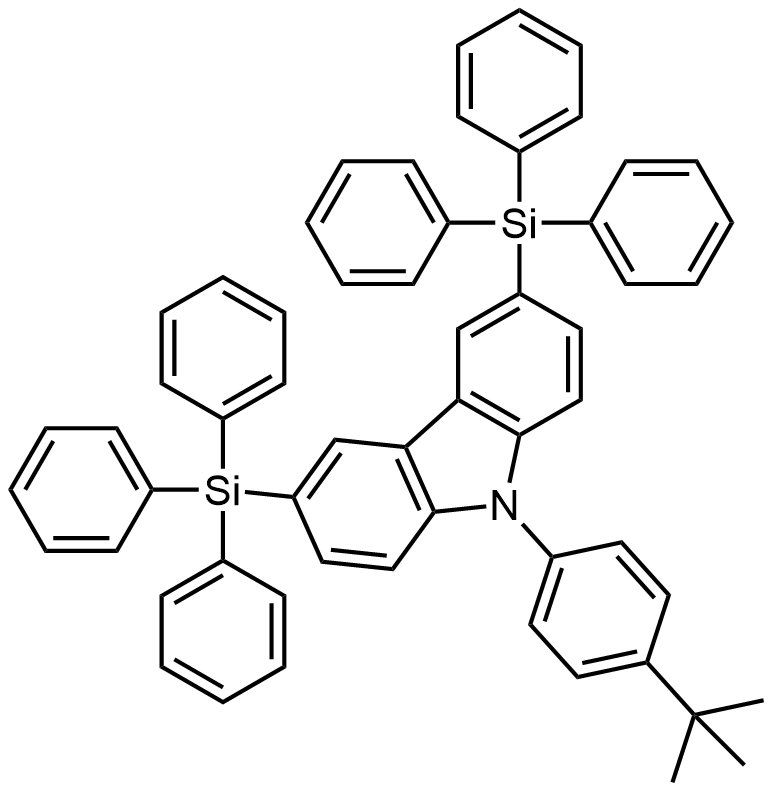

CzSi

| CAS number: | 898546-82-2 |

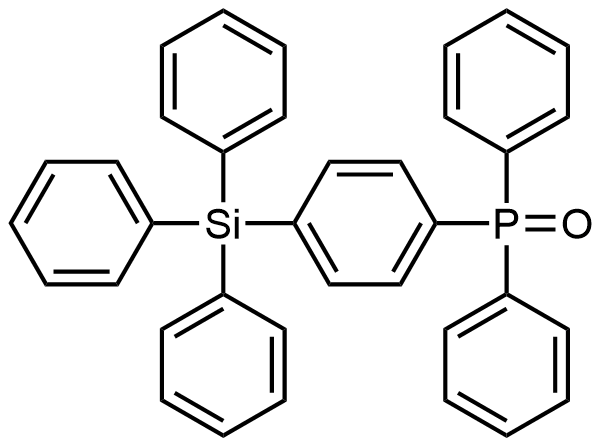

DPPS

| CAS number: | 1152162-74-7 |