TTPA

| CAS number: | 177799-16-5 |

BPPB

| CAS number: | 721969-94-4 |

BTB

| CAS number: | 266349-83-1 |

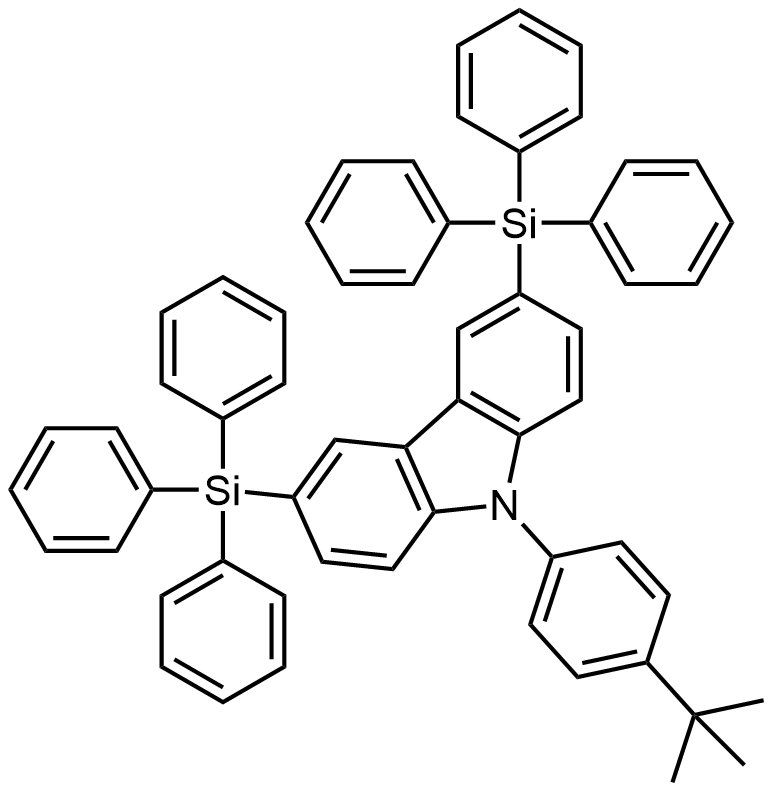

CzSi

| CAS number: | 898546-82-2 |

DNTPD

| CAS number: | 199121-98-7 |

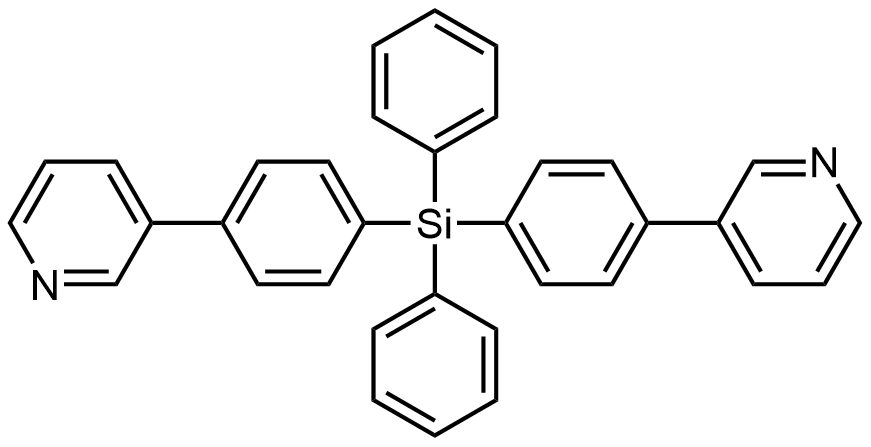

DPPS

| CAS number: | 1152162-74-7 |

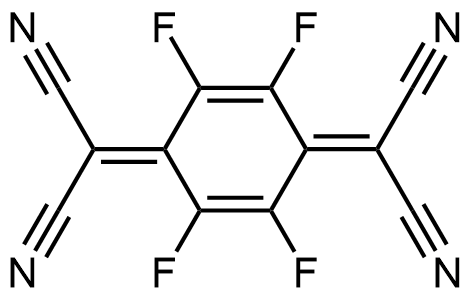

F4TCNQ

| CAS number: | 29261-33-4 |

DPVBi

| CAS number: | 142289-08-5 |

NPB

| CAS number: | 123847-85-8 |

m-MTDATA

| CAS number: | 124729-98-2 |