The content on our website is provided solely for general informational purposes. It should not be considered, nor is it intended to provide advice or recommendations for the purchase, sale, or trade of any products or services. Importantly, the information presented does not constitute an offer to sell or a solicitation of an offer to buy any product.

Please be aware that the availability of our products may vary across different markets due to regulatory restrictions or other considerations. Consequently, not all products or services may be available in your region or country. For specific inquiries regarding the availability and pricing of any product, please contact us at sales@noctiluca.eu.

General information

-

Name:

CuPc

-

Full name:

Copper(II) phthalocyanine

-

CAS number:

147-14-8

-

Chemical formula:

C32H16CuN8

-

Molecular weight:

576.08 g/mol

-

Absorption:

λmax = 345 nm, 631 nm in DCM

-

Photoluminescence:

λmax = 404 nm in film

-

HOMO/LUMO:

HOMO ~ 5.2 eV, LUMO ~ 3.5 eV

-

Synonyms:

Phthalocyanine blue, Pigment Blue 15

-

Classification:

Light-emitting diodes, Hole injection layer materials (HIL), Organometallic, Polymer solar cells, Perovskite solar cells

-

Purity:

Sublimed: >99%

-

Melting point:

350 °C, TGA: >430 °C (0.5% weight loss)

-

Appearance:

Dark blue needles/powder

CuPC Specification: The Pinnacle of Organic Electronics

The ever-evolving landscape of organic electronics is enriched by a myriad of materials and compounds. Among them, CuPC fully known as Copper(II) phthalocyanine, stands as a cornerstone in the technology stack of organic devices.

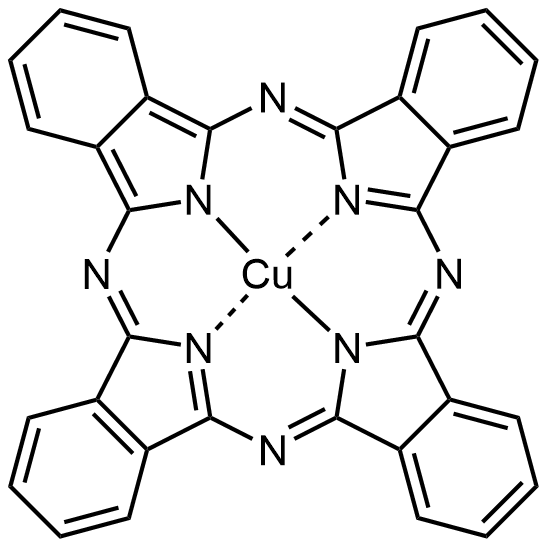

Understanding CuPC

CuPC is an organometallic compound characterized by a copper atom at its core, forming a coordination complex with phthalocyanine. This synthetic blue pigment is not only used in paints and dyes but also holds significant value in the realm of organic electronic devices.

Key Features of CuPC

- Hole Injection Layer Material: CuPC’s electron-rich structure makes it an ideal hole injection layer material in organic light-emitting diodes (OLEDs), enhancing their efficiency and stability.

- Organometallic Properties: The compound’s organometallic nature contributes to its extensive applications, ranging from polymer solar cells to perovskite solar cells.

- Photoconductivity and Catalytic Activity: In thin-film form, CuPC is chemically stable and exhibits both catalytic activity and photoconductivity, making it a versatile material in organic photovoltaics (OPV).

- Applications in Perovskite Solar Cells: CuPC has found applications in inorganic-organic hybrid perovskite solar cells, thanks to its p-type semiconductor behavior.

The Role of CuPC in Contemporary Organic Electronics

In the rapidly evolving field of organic electronics, the quest for materials that deliver superior efficiency, longevity, and energy conservation is relentless. CuPC, distinguished by its organometallic composition and p-type semiconductor characteristics, fulfills these criteria impeccably. Its utilization as a hole injection layer material in light-emitting diodes and its catalytic activity in organic photovoltaics (OPV) make it a material of choice for devices requiring both efficiency and durability.

Conclusion

The organic electronics sector is subject to continuous innovation, necessitating materials that can meet the dual demands of efficiency and durability. CuPC, with its unique coordination complex structure and photoconductive attributes, is well-positioned to significantly influence the trajectory of advancements in organic electronic devices. As scientific research progresses and technological applications broaden, CuPC is expected to find an increasingly diverse range of applications, particularly in organic vacuum-deposited photovoltaics and inorganic-organic hybrid perovskite solar cells.