July 2023

Blog post by Dominika Gonet, Noctiluca.

Sublimation is an endothermic process characterised by the direct transition of a substance from the solid phase to the gas phase, bypassing the liquid phase entirely. This phenomenon takes place under well-defined temperature and pressure conditions, below the substance’s triple point on its phase diagram. The triple point denotes the minimum pressure at which the substance can exist in its liquid state.

Under normal pressures, most chemical compounds and elements exhibit three distinct states at different temperatures. In these cases, the conversion from solid to gas typically involves an intermediate liquid state. It is important to note that the pressure referred to in this context specifically pertains to the partial pressure of the substance itself, not the overall pressure of the entire system, such as atmospheric pressure. Therefore, any solid can undergo sublimation if its vapour pressure exceeds the surrounding partial pressure of the substance, and in some cases, sublimation occurs at a noticeable rate. Certain substances exhibit a greater tendency for sublimation compared to evaporation from the liquid state. This is often due to their considerably high triple point pressures, which presents challenges in obtaining them in liquid form.

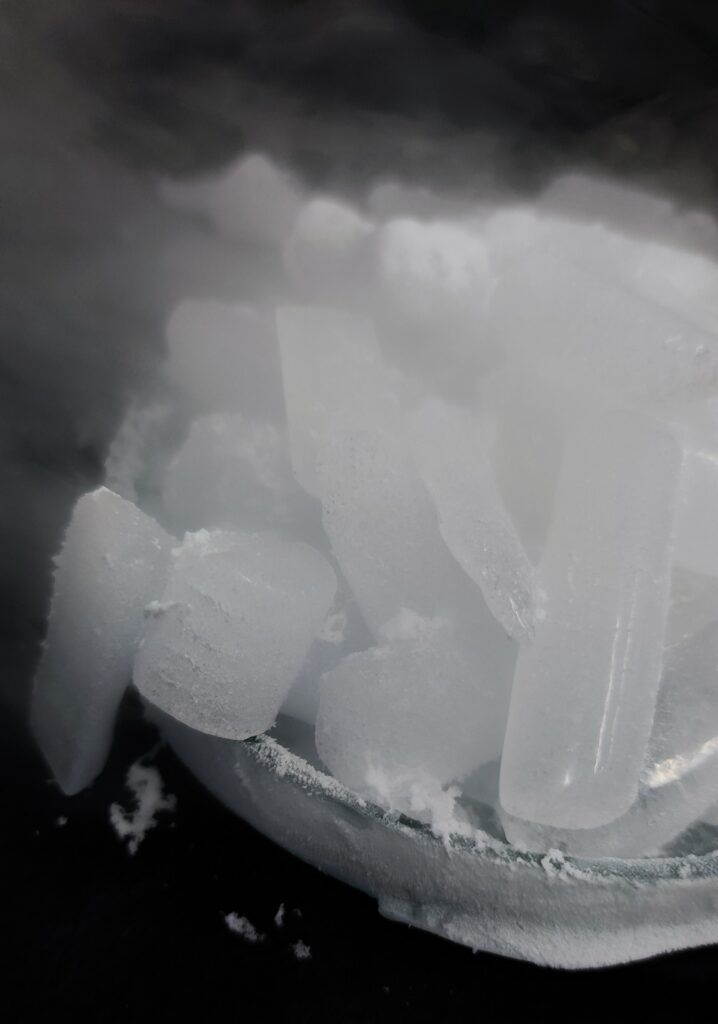

Sublimation is a widely used technique employed by chemists for the purification of compounds. It provides a simpler and more efficient alternative to the laborious and time-consuming method of crystallisation, enabling the purification of even small quantities of substances capable of sublimation. The sublimation process involves placing a solid within a sublimation apparatus and subjecting it to heat under vacuum conditions. By reducing the pressure, the solid undergoes volatilization and subsequently condenses as a purified compound on a cooled surface known as a „cold finger.” Meanwhile, any non-volatile impurities are left behind as a residue. Once heating is discontinued and the vacuum is released, the purified compound can be collected from the cooled surface.

To enhance the efficiency of purification, a temperature gradient is often utilised. This technique allows for the separation of different fractions within the compound. The main purpose of the tube vacuum sublimation instrument is to sublimate the organic mixture under vacuum conditions to achieve the purpose of purification (that is, recrystallization after evaporation). Evaporation of each component typically, an evacuated glass tube is used, which is gradually heated in a controlled manner. By adjusting the temperatures along the length of the tube, the operator can control the regions where re-condensation (recrystallization) occurs. Highly volatile compounds can be completely pumped out of the system or captured by a separate cold trap, moderately volatile compounds re-condense at various points along the tube according to their volatilities, and non-volatile compounds remain concentrated at the hot end.

Sublimation takes place when heat is absorbed, supplying the necessary energy for molecules to overcome the intermolecular forces and transition into the vapour phase. Since this process requires an input of energy, it is classified as an endothermic transformation.

The enthalpy of sublimation, also referred to as the heat of sublimation, can be determined by adding the enthalpy of fusion (the heat needed to convert a solid to a liquid) and the enthalpy of vaporisation (the heat required to convert a liquid to a gas).

What problem do we solve?

Vacuum sublimation is the preferred method for purifying organic compounds. This industry requires extremely high purities, often exceeding 99.99%, to meet the standards for consumer electronics, optical products (such as organic optoelectronic materials for organic light-emitting displays) or nanomaterials and other applications. Sublimation removes not only impurities but also volatiles, which are also a problem in high-temperature manufacturing processes.

Who is it for?

Advancements in Next-Generation Technology Materials

Sublimation services are playing a crucial role in the development of materials for next-generation technologies. Researchers and manufacturers rely on sublimation to enhance to the possible maximum the purity of used compounds at the same time ensuring the outstanding quality and efficiency of a wide range of products in the end use applications such as mobile devices, monitors, solar cells, and more.

Collaboration between Universities and Industries

Sublimation services offer valuable support to leading universities and industrial research laboratories in meeting their purity requirements for the variety of specialised materials. Purification of the compounds by sublimation facilitates a seamless transition from discovery to development and practical application phase for rapidly progressing emerging advanced technologies.

OLED Technology

The rapid advancements in organic electronic technologies present numerous opportunities for diverse and innovative applications. These developing technologies have the potential to improve existing products in terms of power efficiency, size and weight reduction, design flexibility, and overall cost-effectiveness. To make it happen it is necessary to ensure outstanding purity of the compounds to a level of 99.99%.

Sublimation is a method that provides the best solution for final enhancement in purity reaching desired level. Therefore, compounds that undergo the process of purification by sublimation several times are easily utilized in cutting-edge features like flexible OLED displays and transparent light sources.

Perovskite Solar Cells

Sublimation plays a critical role in the development of perovskite materials for solar cells. The objective is to enhance the efficiency and reduce the overall cost of process used in the production of high-quality perovskite materials.

Limitations in the Pharmaceutical Industry

It is important to note that our sublimation services are not available for the manufacturing of drugs, intermediate products, and active pharmaceutical ingredients (API) in the pharmaceutical industry. This limitation arises due to the absence of a cleanroom facility, which is essential for maintaining a sterile and controlled environment necessary for pharmaceutical production processes.

Nevertheless, if such conditions are not required, we are more than happy to discuss possibilities of the final purification step by sublimation.

What can you expect?

Our equipment is able to handle batches ranging in any size from 5g up to 1 kg of material. Efficiency of the purification by sublimation is a combination of many factors, thus for final details please do not hesitate to contact us!