Hole Injection Layer (HIL) in OLEDs: Enhancing Charge Transport and Device Efficiency Introduction to Hole Injection Layer (HIL)

In the intricate world of Organic Light-Emitting Diodes (OLEDs), the Hole Injection Layer (HIL) plays a fundamental role. As a key part of the transport layer, HIL is essential for facilitating the efficient injection of holes from the anode into the active layers of OLEDs. This layer is crucial for improving the electrical properties and overall performance of OLED devices.

The Science of Hole Injection Layer (HIL) in OLEDs

The HIL is designed to optimize the interface between the anode and the organic layers, enhancing hole injection efficiency. Materials used in HIL have suitable energy levels to ease the transfer of holes, reducing the operational voltage and improving the device’s energy efficiency. The selection of HIL materials is critical for ensuring balanced charge transport, which is essential for the longevity and stability of OLED displays.

Advantages of Utilizing HIL in OLED Industry

- Improved Charge Transport: The use of HIL materials is key to significantly enhancing the injection and movement of holes, which is essential for the efficient operation of OLED devices. This improvement in charge transport leads to faster response times and reduced power consumption, making OLED devices more energy-efficient and environmentally friendly.

- Enhanced Device Stability: An effective HIL plays a vital role in maintaining the stability of OLED displays over extended periods. By promoting a uniform charge distribution, it minimizes the risk of hot spots and uneven wear, which can lead to premature degradation. This results in OLED devices with longer operational lifespans, reducing the need for frequent replacements and thereby lowering the overall cost of ownership.

- Superior Display Performance: Optimized hole injection provided by high-quality HIL materials leads to better luminance, ensuring that OLED screens can display brighter and more vibrant images. Additionally, the enhanced color balance made possible by efficient HIL contributes to more accurate and lifelike color reproduction, crucial for applications where visual fidelity is paramount, such as high-definition televisions and premium smartphones.

Industry Applications of Hole Injection Layer (HIL)

HIL is vital in various OLED applications, including high-end televisions, smartphones, and innovative lighting systems. Its role in enhancing charge transport efficiency makes it crucial in manufacturing OLED panels for consumer electronics and commercial displays. HIL technology is also integral to the development of advanced OLED applications, where energy efficiency and display performance are key.

In summary, the integration of Hole Injection Layer (HIL) materials represents a significant advancement in OLED technology. These hole transport layer materials are essential for enhancing the performance, efficiency, and stability of OLED devices. High-quality HIL materials, such as those provided by Noctiluca, are crucial for producing OLED displays with superior quality and longevity. The application of these materials not only optimizes device functionality but also extends the range of OLED applications across various industries, highlighting their importance in the ongoing evolution of OLED technology.

Noctiluca: Your Trusted Partner in the OLED Materials Market

As a leading OLED material supplier, Noctiluca is dedicated to shaping the future of the OLED materials market with our advanced, high-quality products. Renowned among OLED material suppliers for our commitment to innovation and excellence, we serve a pivotal role in addressing the diverse needs of this dynamic industry. As a reliable OLED materials supplier, we focus on delivering cutting-edge materials that propel the development of OLED technology, ensuring that our clients stay ahead in the competitive OLED materials market.

Key HIL Materials Offered by Noctiluca

Noctiluca provides a selection of high-quality materials for Hole Injection Layers in OLEDs:

- DPVBi (142289-08-5): Esteemed for its excellent hole-transporting properties, DPVBi is instrumental in enhancing the efficiency and brightness of OLED devices, making it an ideal choice for high-quality displays.

- TCTA (139092-78-7): Known for facilitating effective hole injection, TCTA contributes significantly to the improved performance and color accuracy in OLED displays, especially in high-resolution applications.

- TAPC (58473-78-2): Offers improved hole injection efficiency, crucial for high-brightness OLED applications, ensuring vibrant and consistent color output across various display types.

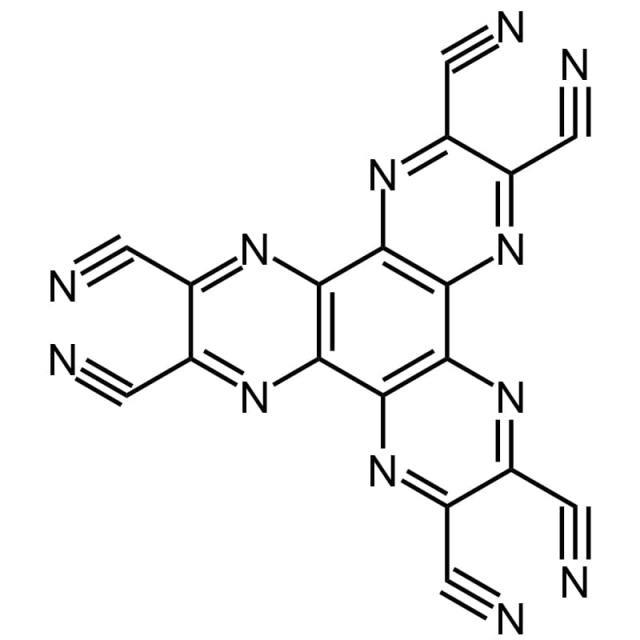

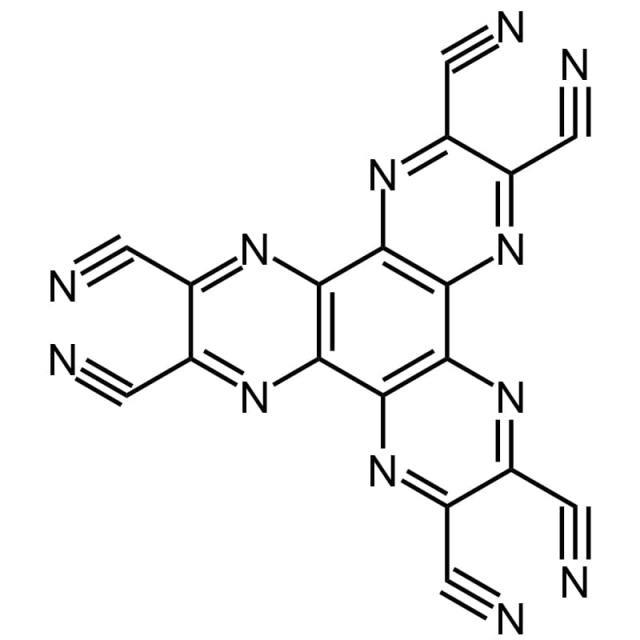

- PPDN (215611-93-1): Renowned for its balanced charge transport and stability, PPDN is a popular choice for HIL in OLEDs, contributing to the durability and longevity of the devices.

- NPB-DPA (910058-11-6): Effective in enhancing hole injection and transport, NPB-DPA is widely used in various OLED structures for its reliable performance and contribution to device efficiency.

- NPNPB (936355-01-0): Similar to NPB-DPA, NPNPB is known for its efficacy in improving hole transport and injection, playing a key role in the functionality and efficiency of OLEDs.

- CBP (58328-31-7): Distinguished by its high hole mobility, CBP facilitates efficient operation of OLED devices, making it an energy-efficient option for HIL applications.

- TCP (148044-07-9): Known for its role in improving overall performance and efficiency of OLED displays, TCP is an essential material in achieving optimal display quality and longevity.

- TPD (65181-78-4): Offers unique properties that contribute to high-efficiency OLED applications, enhancing both brightness and color fidelity, crucial for high-end display technologies.

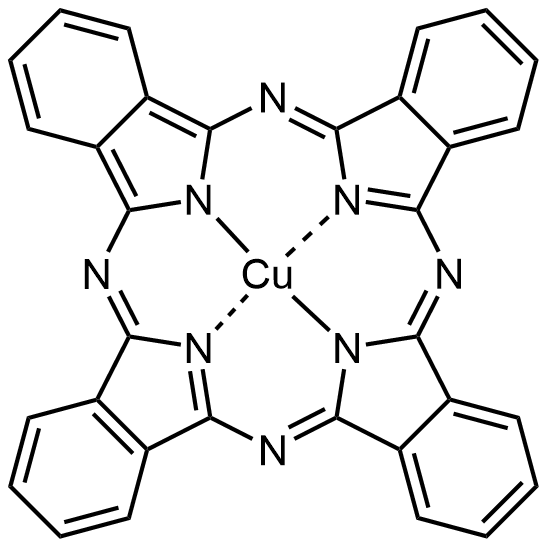

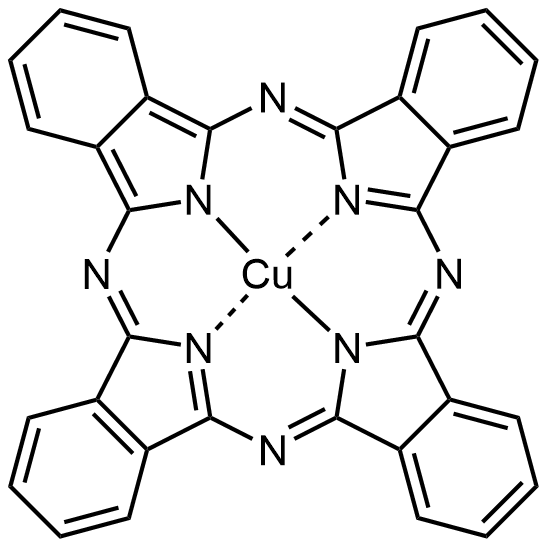

- CuPc (147-14-8): Esteemed for its effectiveness in hole transport and injection, CuPc is vital for achieving high-quality color and operational stability in OLED applications.

…and many more. Explore our full list on our website.

If the specific HIL material you are searching for is not listed in our collection, we invite you to contact us for specialized assistance. Our dedicated team is committed to providing bespoke solutions that cater to your unique requirements in OLED technology, ensuring you have access to the highest quality materials for your specific OLED applications.